PCB aluminum sheet_1100 aluminum sheet performance advantages for pcb aluminum substrate

Circuit boards are widely used in electronic products and digital products. Circuit boards are composed of circuit layers, thermal insulation layers and substrates.

PCB circuit board substrate materials are mainly divided into two categories:

- Organic material substrates, including phenolic resin, glass fiber/epoxy resin (FR4), Polyimide, BT/Epoxy, etc.;

- Inorganic material substrates, including inorganic metal substrates (copper substrates, aluminum substrates, etc.), ceramic plates, etc.

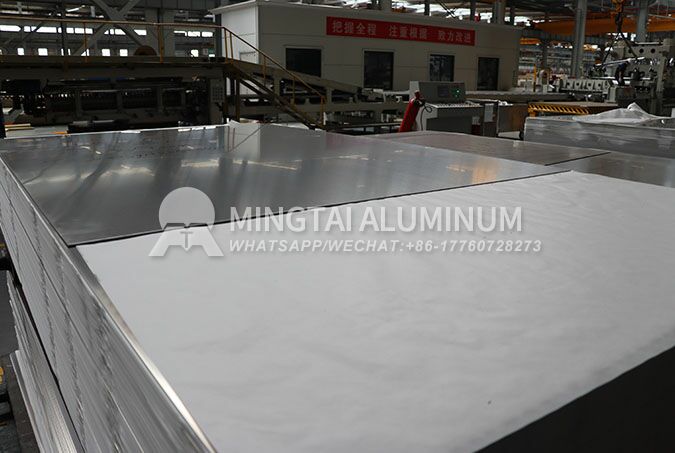

The metal substrate is made of 0.3mm-2.Omm thick metal plates, such as aluminum substrates, iron substrates, copper substrates, epoxy resin semi-cured sheets and copper foils, which are thermally composited and pressed. PCB aluminum sheets generally use aluminum alloy plates, such as 1100 aluminum plates, 5052 aluminum plates, etc. PCB aluminum substrates have good thermal conductivity, electrical insulation and mechanical processing properties, meeting the requirements of later processing.

1100-H18 aluminum plate for PCB aluminum sheet

1100 is industrial pure aluminum with an aluminum content (mass fraction) of 99.00%. It cannot be strengthened by heat treatment. It has high corrosion resistance, electrical conductivity and thermal conductivity, low density, good plasticity, and can produce various aluminum materials through pressure processing, but low strength. Other process performance is basically the same as 1050A. 1100 is usually used for applications that require good forming performance, high corrosion resistance, and do not require high strength, such as food and chemical handling and storage equipment, sheet metal products, hollow hardware processed by drawing or spinning, welding combination keys, reflectors, nameplates, etc.

PCB aluminum substrate performance advantages

(1) Good mechanical properties: Metal substrates have good mechanical strength and toughness. Solve the brittleness problem of circuit boards with inorganic material substrates. It is suitable for large-area patch processing and can also withstand the installation of heavy components. In addition, the dimensional stability and flatness of the metal substrate are its major advantages.

(2) Good heat dissipation performance: Since the metal substrate and the prepreg are in direct contact, they both have excellent heat dissipation performance. When using a metal substrate for patch processing, the heat generated during patch processing can be well dissipated. The heat dissipation capacity of the circuit board depends on the thickness of the metal substrate and the thickness of the resin layer.

(3) Ability to shield electromagnetic waves: In high-frequency circuits, designers focus on preventing electromagnetic wave radiation. Metal substrates can form a natural protective layer to achieve the purpose of shielding electromagnetic waves.