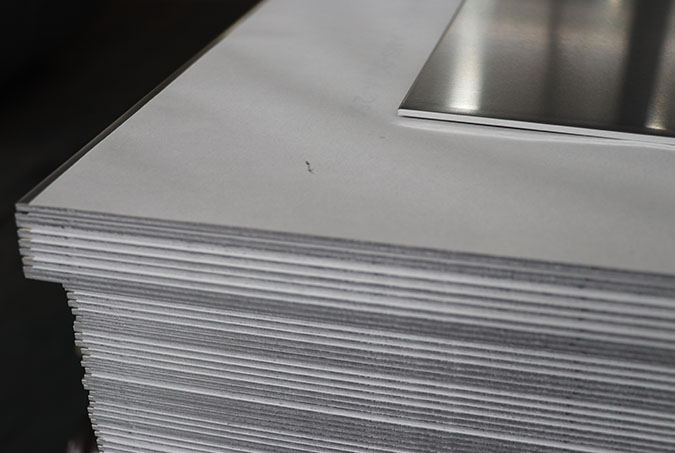

3003 O Aluminum Sheet: The Ideal Choice for Power Battery Shells

In the booming field of new energy, power batteries are the core components of electric vehicles and energy storage systems. The choice of materials for power battery shells is crucial for ensuring battery safety, performance, and lifespan. The 3003 O aluminum sheet has emerged as a top – tier option, bringing a host of advantages to the power battery manufacturing industry.

The 3003 aluminum alloy belongs to the 3000 series, with manganese (Mn) as the main alloying element, usually present in a proportion of about 1.0% – 1.5%. Manganese plays a vital role in enhancing the strength and workability of the alloy. The “O” temper indicates that the sheet is in the annealed state, which endows it with excellent formability and ductility. This unique combination of alloy composition and temper makes the 3003 O aluminum sheet stand out for specific applications.

Specification of 3003 O aluminum sheet for power battery shell

| Alloy | 3003 aluminum sheet |

| Temper | O,H14 |

| Thickness(mm) | 0.8-3.0 |

| Width(mm) | C |

| Length(mm) | C |

| Standard | ASTM B209/EN 485/GB/T 33227-2016/JIS H4000 |

Advantages of 3003 O aluminum sheet for power battery shell

◆Formability: The 3003 O aluminum sheet exhibits outstanding formability. It can be easily shaped into complex geometries through processes such as deep drawing and stamping. Power battery shells often require precise and intricate designs, and the 3003 O aluminum sheet can meet these requirements with ease. This allows manufacturers to produce battery shells with uniform thickness and accurate dimensions, ensuring the proper fit and function of internal battery components.

◆Corrosion Resistance: With its inherent corrosion – resistant properties, the 3003 O aluminum sheet is well – suited for protecting power batteries. Batteries may be exposed to various environmental factors, including moisture and chemical substances. The aluminum sheet forms a thin, protective oxide layer on its surface, which acts as a barrier against corrosion. This not only safeguards the integrity of the battery shell but also extends the lifespan of the battery by preventing external elements from infiltrating and affecting the internal electrochemical reactions.

◆Thermal Conductivity: Aluminum, in general, has good thermal conductivity, and the 3003 O aluminum sheet is no exception. In power batteries, heat management is crucial to maintain optimal performance and safety. The 3003 O aluminum sheet can effectively dissipate heat generated during battery operation, helping to prevent overheating and thermal runaway. This property ensures the stable operation of power batteries, especially during high – load and fast – charging scenarios.