5052 Aluminum Coil

Introduction

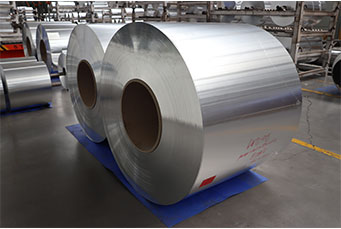

5052 Aluminum coil is an AL-Mg alloy, contains nominally 2.5% magnesium and 0.25% chromium, has good corrosion resistance, good weldability, good cold workability, medium strength, good material formability, suitable for various sheet metal processing such as stamping and bending, and good anodic oxidation. 5052 Aluminum coil has high strength, especially high fatigue resistance, high plasticity and corrosion resistance, good weldability, poor machinability, and can be polished.

The Introduction of 5052 Aluminum Coil

5052 Aluminum coil is an AL-Mg alloy, contains nominally 2.5% magnesium and 0.25% chromium, has good corrosion resistance, good weldability, good cold workability, medium strength, good material formability, suitable for various sheet metal processing such as stamping and bending, and good anodic oxidation. 5052 Aluminum coil has high strength, especially high fatigue resistance, high plasticity and corrosion resistance, good weldability, poor machinability, and can be polished.

The fatigue properties of 5052 aluminum coil are excellent, H32 temper is 115 MPa and H34 temper is 123 MPa. Compared to the other 5 series aluminum alloys, 5052 aluminum coil has midway alloying content and strength. In slightly alkaline environments, 5052 aluminum coil shows a resistance level. Its resistance to marine environments is better than 5005 alloy, making 5052 aluminum coil become more popular for marine applications.

The Product Specification of 5052 Aluminum Coil

|

Alloy |

5052 aluminum coil strip |

|

Temper |

F, O, H12, H14, H16, H18, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, etc. |

|

Thickness (mm) |

0.2-8.00 |

|

Width (mm) |

100-2650 |

|

Length (mm) |

C |

|

ID |

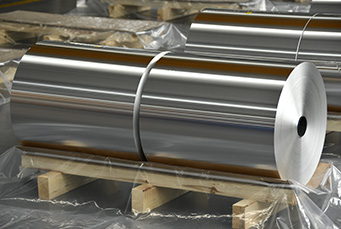

Ø505mm or customized |

|

Surface |

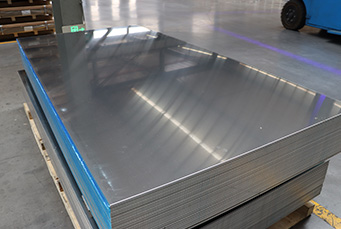

Mill finish surface, bright, polished surface, with blue PVC films or paper interleaved |

|

Package |

Eye to sky or Eye to wall |

|

Certificate |

DNV,ABS,CCS,BV |

|

Application |

Ships, automobiles, fuel tank, transportation equipment, etc. |

|

Sample |

Available |

Chemical composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Zr |

Others |

AL |

|

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.20-2.80 |

0.15-0.35 |

0.10 |

- |

- |

Single |

Total |

Balance |

|

0.05 |

0.15 |

|||||||||||

Mechanical properties

|

Alloy & Temper |

Tensile strength 25℃/Mpa |

Yield strength 25℃/Mpa |

Elongation % |

Hardness HB |

|

5052-H32 |

210-260 |

130 |

5 |

61 |

Physical properties

|

Alloy & Temper |

Thermal expansion coefficient(20-100℃) µm/m•k |

Melting point range(℃) |

Conductivity 20℃(68°F) (%IACS) |

Resistivity 20(68°F)Ωmm2/m |

Density(20℃)(g/cm³) |

|

5052-H32 |

23.8 |

607-649 |

35 |

0.0493 |

2.73 |

The Product Features of 5052 Aluminum Coil

● 5052 Aluminum coil has strong plasticity, good corrosion resistance, good weldability and good cold working performance.

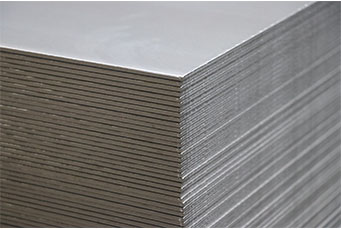

● The surface of 5052 aluminum coil has no peeling, air bubbles, surface roughness and local mechanical damage.

● 5052 Aluminum coil has good corrosion resistance, weldability, plasticity, and certain tensile strength, yield strength, elongation, impact resistance, and other properties.

● 5052 aluminum coils can be processed by cold rolling, hot rolling and other methods to form products of different shapes and sizes.

The Application of 5052 Aluminum Coil

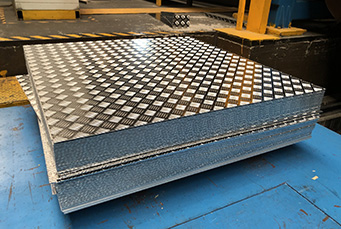

5052 aluminum coils are mainly used in checkered plates, umbrella frames, special materials for transportation equipment, automotive fuel tanks, lighting, non-slip floors, etc.

5052 Aluminum coil for automobiles: covers and parts, truck shock absorbers, side panels of semi-trailers, etc.

5052 Aluminum coil for ships: ship construction, such as a deck, ship side, bottom plate, wheelhouse, porthole, mast, and so on.