5052 Aluminum Alloys for Refrigerated Trucks

5052 aluminum alloy is widely utilized in the manufacture of refrigerated trucks due to its excellent properties that meet the demanding requirements of the refrigeration industry. This alloy is particularly known for its excellent corrosion resistance, formability, and weldability, making it an ideal choice for creating durable and reliable components.

Key Features of 5052 Aluminum Alloy

●Corrosion Resistance:

The 5052 alloy offers outstanding resistance to corrosion, especially in humid and cold environments typical in refrigerated applications. This makes it suitable for the exterior as well as the internal structures of refrigerated trucks.

●Good Strength-to-Weight Ratio:

With a high strength-to-weight ratio, 5052 aluminum adds minimal weight to the truck while providing sufficient strength to withstand various stresses during operation.

●Excellent Formability:

This alloy can be easily formed into various shapes and sizes, allowing for customization in refrigerated truck designs. It can be easily bent, rolled, or drawn without compromising its structural integrity.

●Weldability:

5052 aluminum can be welded effectively using various welding techniques. This property is essential for fabricating truck bodies and insulation partitions, ensuring strong joints and a secure construction.

●Thermal Conductivity:

While not the highest among all aluminum alloys, the thermal conductivity of 5052 is adequate for refrigerated applications, helping to manage temperature efficiently.

Applications in Refrigerated Trucks

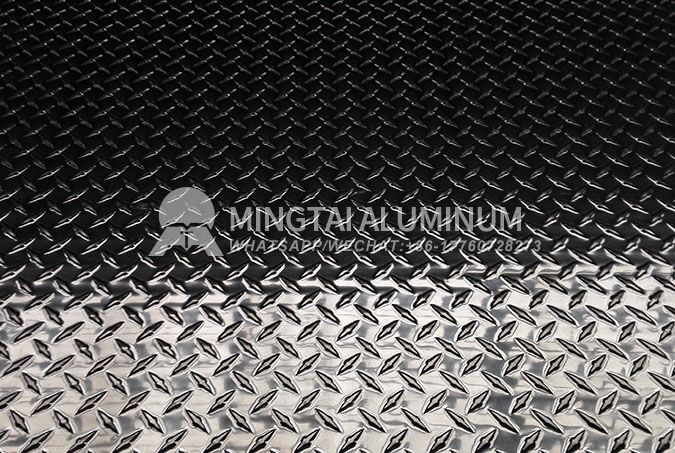

●Truck Bodies: The 5052 aluminum sheets and plates are frequently used for the structural panels of refrigerated trucks, providing a lightweight structure that can withstand harsh conditions.

●Insulation Panels: Aluminum strips can be used to create insulated panels that improve thermal efficiency, keeping perishable goods at the desired temperature during transport.

●Flooring: The high durability of 5052 makes it ideal for flooring applications within refrigerated trucks, where it can resist impacts and maintain integrity over time.

Interior Walls and Shelving: The alloy’s resistance to corrosion and ease of cleaning make it suitable for the interior surfaces of refrigerated trucks, ensuring hygiene and performance.

5052 aluminum alloy strips, plates, and sheets are essential materials for the construction of refrigerated trucks. Their unique combination of strength, corrosion resistance, and formability make them the preferred choice in the industry.

For suppliers and detailed specifications, please contact manufacturers specializing in aluminum products for transportation and cold storage solutions. Whether you are looking to build new refrigerated trucks or upgrade existing ones, 5052 aluminum can provide the durability and performance you need.