5052 Anodizing Aluminum Plate for Keyboard Manufacturing

In the competitive world of electronic peripherals, keyboard manufacturers continuously seek materials that balance durability, tactile appeal, and cost efficiency. 5052 Anodizing aluminum plate has emerged as the ideal solution for premium keyboard construction, offering a winning combination of structural integrity and surface refinement.

Key Features of 5052 Anodizing Aluminum for Keyboards

The 5052 alloy’s inherent properties make it perfectly suited for keyboard applications:

●Corrosion Resistance: Withstands hand perspiration and environmental humidity, maintaining pristine appearance

●Anodizing Compatibility: Creates hard, wear-resistant surface layer (40-60μm thickness)

●Formability: Easily stamped into complex keyboard geometries with sharp details

●Thermal Conductivity: Effectively dissipates heat from LED lighting and processor components

●Lightweight Strength: 5052’s high strength-to-weight ratio enables thinner profiles without sacrificing rigidity

Why Anodization Matters for Keyboard Quality

The anodizing process delivers critical advantages for keyboard performance:

●Surface Hardening: Increases wear resistance to 650-700 HV (vs. 90 HV for raw aluminum)

●Aesthetic Customization: Enables vibrant color options through electrolytic dyeing

●Fingerprint Resistance: Smooth Anodizing surface repels oils and smudges

●Electrical Insulation: Protects internal components from short circuits

Applications Beyond Keyboards: Diversified Electronic Uses

While keyboards remain its primary application, 5052 Anodizing aluminum excels in:

●Laptop palm rests and bezels

●Gaming console casings

●Smartphone mid-frames

●Audio equipment enclosures

●Wearable device housings

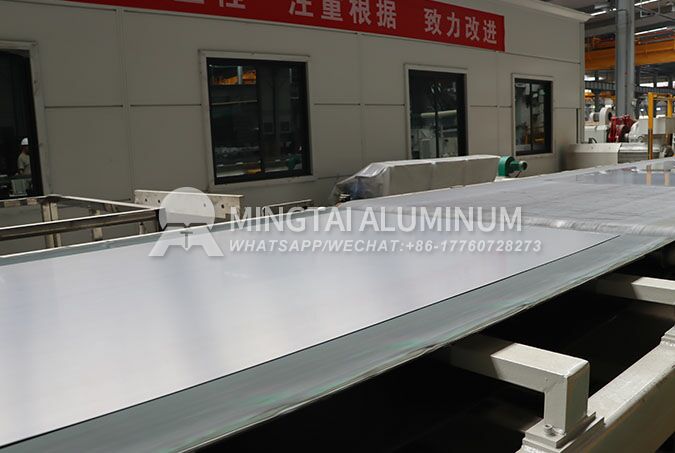

Why Choose Mingtai Aluminum for Keyboard Materials?

Mingtai Aluminum has earned global recognition as a premium 5052 aluminum supplier:

●Precision Manufacturing: ±0.02mm thickness tolerance for consistent key travel

●Surface Finish Expertise: Achieves 0.4μm Ra surface roughness after polishing

●Anodizing Pre-Treatment: Proprietary cleaning process ensures optimal coating adhesion

●Batch Consistency: Advanced rolling mills maintain mechanical properties within 5% variance

●Certified Quality: Compliant with ISO 9001:2015 and RoHS environmental standards

The Mingtai Advantage: More Than Just a Supplier

What sets us apart in the competitive aluminum industry?

●Material Science Collaboration: Work with our metallurgists to optimize alloy composition for specific switch types

●Global Logistics Network: Streamlined supply chain management ensures timely deliveries to manufacturing hubs worldwide

●Technical Documentation: Comprehensive mill test reports with each shipment

●Post-Sale Support: Anodizing process optimization assistance available

Contact Mingtai Aluminum Today

Ready to elevate your keyboard manufacturing capabilities? Reach out to our specialists:

Email: sales@mingtai-al.com

WhatsApp/WeChat: +86-17760728273

Website: www.mingtaialuminum.com

When precision and performance matter most, Mingtai Aluminum’s 5052 Anodizing aluminum plates deliver unmatched value. With two decades of industry experience and a customer-centric approach, we empower manufacturers to create keyboards that combine exceptional durability with sophisticated aesthetics.