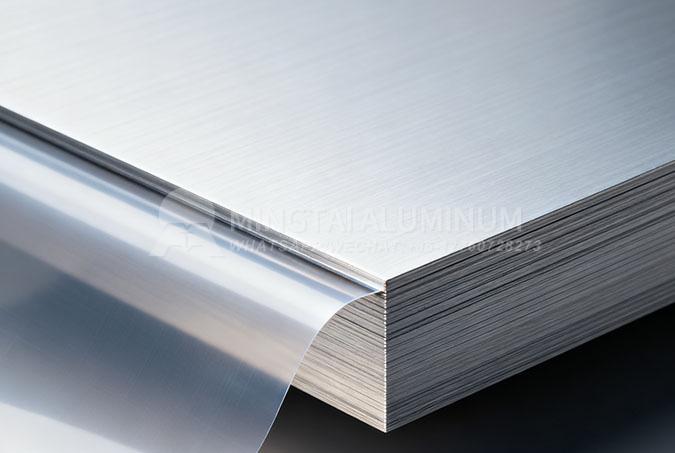

6061 T6 Aluminum Plate for CNC Milling Machining

CNC milling machining demands materials that combine exceptional dimensional stability, superior mechanical strength, excellent machinability, and consistent quality to achieve high-precision parts production. As a heat-treated 6-series Al-Mg-Si alloy, 6061 T6 aluminum plate stands out as the ultimate choice for CNC milling applications, delivering the perfect balance of rigidity, workability, and post-processing stability. Henan Mingtai AL. Co, Ltd. (stock code: 601677), a leading aluminum processor with 27 years of expertise, produces premium 6061 T6 aluminum plates tailored for CNC milling. Compliant with ASTM B209, ISO 9001, and IATF 16949 standards, Mingtai’s products are trusted by manufacturers worldwide for precision components in aerospace, automotive, machinery, and electronics industries.

1. Core Advantages of 6061 T6 Aluminum Plate for CNC Milling Machining

Mingtai’s 6061 T6 aluminum plate is engineered to address the key requirements of CNC milling, offering four critical benefits that enhance processing efficiency and part quality:

Superior Mechanical Strength & Rigidity: After T6 solution heat treatment and artificial aging, 6061 aluminum achieves a tensile strength of 276-310MPa and yield strength of ≥241MPa—30% stronger than annealed aluminum alloys. This high strength prevents workpiece deformation during high-speed milling, ensuring tight tolerances (±0.005mm) for precision components like aerospace brackets and automotive parts.

Excellent Machinability for Smooth Processing: The alloy’s uniform grain structure (refined via Mingtai’s precision rolling) and optimal hardness (65-75 HB) reduce tool wear and improve chip evacuation. It supports high cutting speeds (1500-3000 rpm) and feed rates (0.1-0.3 mm/rev) for CNC milling, reducing processing time by 20-30% compared to harder alloys like 7075. The material’s low cutting resistance also extends tool life by 40%, lowering production costs.

Exceptional Dimensional Stability Post-Machining: 6061 T6 aluminum plate exhibits minimal thermal expansion (23.1 × 10⁻⁶ /℃) and low residual stress (eliminated via stress-relief annealing). This ensures parts maintain their shape and dimensions even after complex milling operations (e.g., pocketing, profiling, and threading), reducing scrap rates to below 0.5% in mass production.

Versatile Post-Processing Compatibility: After CNC milling, 6061 T6 aluminum plate readily accepts anodizing, painting, welding, and bonding—critical for finished parts requiring corrosion resistance or aesthetic appeal. Its anodized surface (hardness ≥500 HV) enhances wear resistance, making it suitable for high-wear components like machine tool fixtures.

2. Key Technical Specifications of 6061 T6 Aluminum Plate for CNC Milling

Mingtai provides customized 6061 T6 aluminum plate solutions to match diverse CNC milling requirements, with core parameters optimized for precision and processing efficiency:

|

Alloy |

Temper |

Thickness Range (mm) |

Width Range (mm) |

Key Mechanical Properties |

Compliance Standards |

|

6061 |

T6 |

2.0-50.0 (customizable up to 300mm) |

1000-2600 (customizable) |

Tensile Strength: 276-310MPa; Yield Strength: ≥241MPa; Elongation: ≥10%; Hardness: 65-75 HB |

ASTM B209, ISO 6361, IATF 16949, GB/T 3880 |

Additional CNC Milling-Critical Indicators

Surface Quality: Smooth and flat with no scratches, oxidation, or impurities; surface roughness Ra ≤0.8μm to ensure uniform tool contact and precise milling.

Dimensional Precision: Thickness tolerance ±0.02mm; flatness ≤1mm/m; edge straightness ≤0.5mm/m—critical for fitting into CNC milling fixtures without alignment issues.

Chemical Composition (wt%): Si: 0.4-0.8; Fe: ≤0.7; Cu: 0.15-0.40; Mn: ≤0.15; Mg: 0.8-1.2; Cr: 0.04-0.35; Zn: ≤0.25; Al (balance)—optimized for machinability and strength.

Cleanliness: Oil content ≤5mg/m²; particle count (≥0.5μm) ≤10 particles/㎡—meeting cleanroom standards for precision component manufacturing.

3. CNC Milling Adaptability & Processing Recommendations

Mingtai’s 6061 T6 aluminum plate is fully compatible with all CNC milling processes, supporting the production of complex, high-precision parts. Below are key processing recommendations to maximize efficiency:

Cutting Tools: Use carbide end mills (3-4 flutes) for optimal chip removal; coated tools (TiAlN) further extend life and improve surface finish.

Cutting Parameters: For rough milling: speed = 1500-2000 rpm, feed rate = 0.2-0.3 mm/rev, depth of cut = 2-5mm. For finish milling: speed = 2500-3000 rpm, feed rate = 0.1-0.15 mm/rev, depth of cut = 0.1-0.5mm.

Coolant Selection: Apply water-soluble coolant (5-10% concentration) to reduce cutting temperature and prevent workpiece warping—critical for deep-pocket milling or high-speed operations.

Post-Machining Treatments: Stress-relief annealing (150-200℃ for 2-3 hours) for complex parts; anodizing (Type II/III) for corrosion resistance; and laser engraving for part identification.

4. Mingtai’s Strength as a Supplier of 6061 T6 Aluminum Plate for CNC Milling

Mingtai’s advanced production capabilities, strict quality control, and customer-centric services make it a trusted partner for manufacturers relying on CNC milling:

Precision Production Equipment: Equipped with China’s first “1+4” hot continuous rolling line, CVC 6-roller cold rolling mills, and precision heat treatment furnaces, Mingtai ensures uniform grain structure and thickness tolerance (±0.02mm) across all batches. The company’s annual output of 6061 T6 aluminum plate exceeds 80,000 tons, supporting large-scale CNC milling projects.

Rigorous Quality Assurance: Mingtai’s CNAS-accredited testing center conducts 100% batch inspections, including mechanical property testing (tensile, hardness, elongation), dimensional measurement, and surface defect detection. Each shipment includes a detailed mill test certificate (MTC) for traceability, ensuring compliance with aerospace (AMS 4027) and automotive (ISO 16283) standards.

Customization & Fast Delivery: Supports tailored thickness (2.0-300mm), width (1000-2600mm), and cutting (slitting, shearing) to match CNC milling machine specifications. In-stock standard sizes ship within 3-7 days; custom orders are delivered in 15-30 days (MOQ: 1 ton). Global logistics partnerships ensure timely delivery to 70+ countries.

Technical Support for CNC Milling: Mingtai’s team of 600+ professional engineers provides free processing consultations, including cutting parameter optimization, tool selection, and post-machining treatment recommendations. Free 1-5kg samples are available for pre-production testing to validate compatibility with specific CNC milling processes.

5. Why 6061 T6 Aluminum Plate Outperforms Alternatives for CNC Milling

Compared to other aluminum alloys and materials, Mingtai’s 6061 T6 aluminum plate offers distinct advantages for CNC milling:

Better Machinability Than 7075 Aluminum: 7075 aluminum is stronger but harder (100-110 HB), increasing tool wear and processing time; 6061 T6 balances strength and workability, ideal for high-volume precision parts.

Higher Strength Than 5052 Aluminum: 5052 aluminum (tensile strength: 230-280MPa) lacks sufficient rigidity for complex milling, leading to workpiece deformation; 6061 T6’s higher strength ensures dimensional stability.

More Cost-Effective Than Steel: Steel is heavier (increasing CNC machine load) and prone to rust; 6061 T6 aluminum reduces part weight by 60% and eliminates corrosion issues, lowering lifecycle costs.

Contact Mingtai for 6061 T6 Aluminum Plate for CNC Milling Machining

If you’re a manufacturer seeking high-quality 6061 T6 aluminum plate for CNC milling, Mingtai offers reliable, precision-engineered solutions tailored to your processing needs. Our technical team provides free sample testing and customized recommendations to optimize your CNC milling efficiency and part quality.

Email: sales@mingtai-al.com

Whatsapp/Wechat: +86-17760728273

Website: www.mingtaialuminum.com

Mingtai Aluminum is committed to delivering premium 6061 T6 aluminum plate that empowers CNC milling operations with superior performance, consistency, and value—supporting your success in precision manufacturing!