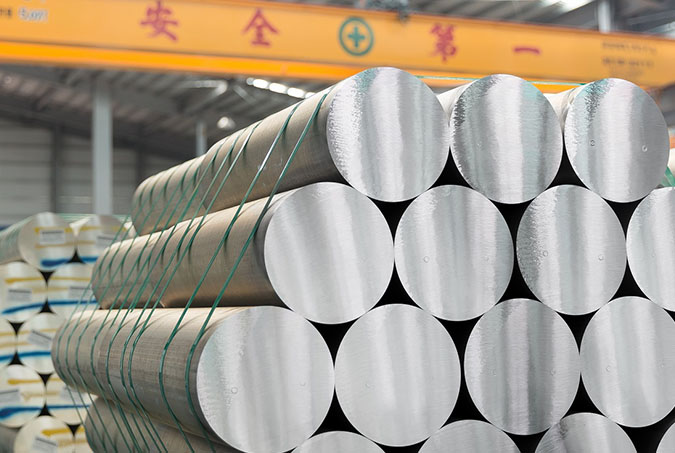

6063 Aluminum Round Bar

Introduction

6063 aluminum bars belong to low-alloy Al-Mg-Si series high plasticity alloys, known for their excellent surface finish, with excellent extrusion performance, good corrosion resistance and comprehensive mechanical properties, and are susceptible to oxidization discoloration.

The Introduction of 6063 aluminum round bar

6063 aluminum bars belong to low-alloy Al-Mg-Si series high plasticity alloys, known for their excellent surface finish, with excellent extrusion performance, good corrosion resistance and comprehensive mechanical properties, and are susceptible to oxidization discoloration.

The Product Specification of 6063 aluminum round bar

|

Alloy |

6063 aluminum round bar |

|

Temper |

T6 |

|

Diameter |

30-200mm |

|

Length (mm) |

customized as required |

|

MOQ |

5 TON |

6063 aluminum rod typical mechanical properties

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T5, T52 | 27 | 186 | 21 | 145 | 12 | 60 |

| T6 | 35 | 241 | 31 | 214 | 12 | 73 |

Typical chemical composition

| Element | Composition % | |

| Si | 0.20-0.6 | |

| Fe | 0.35 | |

| Cu | 0.1 | |

| Mn | 0.1 | |

| Mg | 0.45-0.9 | |

| Cr | 0.1 | |

| Ni | - | |

| Zn | 0.1 | |

| Ti | 0.1 | |

| Other | Each | 0.05 |

| Total | 0.15 | |

| Al | Remainder | |

Characteristics of 6063 aluminum rod

● Strengthened through heat treatment with high impact toughness and insensitive to notches.

● Excellent thermoplasticity, can be extruded at high speeds into complex structural shapes, thin-walled and hollow sections, or forged into complex structural forgings.

● Excellent weldability and corrosion resistance with no tendency to stress corrosion cracking. Among heat-treatable aluminum alloys, Al-Mg-Si alloys are the only alloys where stress corrosion cracking has not been observed.

● Processed surfaces are very smooth and readily anodized and colored.