How Aluminum Drives the Future of Automotive Lightweighting: A Manufacturer’s Perspective

1.Introduction

The global push for fuel efficiency and emission reduction has made automotive lightweighting a top priority. As a trusted aluminum supplier for Tesla, BMW, and BYD, Mingtai Aluminum explores how advanced aluminum alloys are reshaping vehicle design—from EV battery enclosures to structural components.

2.Why Aluminum?

◆Strength-to-Weight Ratio

“Aluminum reduces vehicle weight by 40% vs. steel, improving energy efficiency by 10-15%.”

◆Corrosion Resistance

Marine-grade 5052 aluminum sheets in electric bus frames

◆Sustainability

95% of automotive aluminum is recyclable, cutting lifecycle CO2 by 80%.”

3.Key Applications in Modern Vehicles

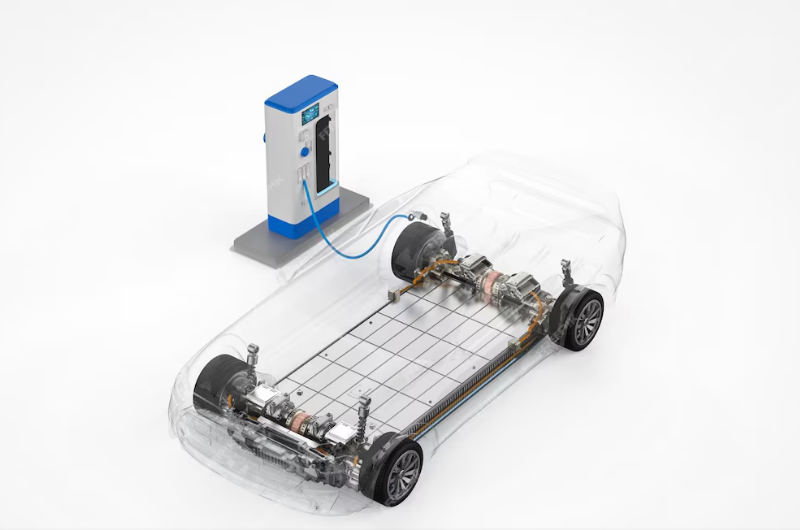

◆EV Battery Trays & Enclosures

High thermal conductivity (6061-T6 alloy) + electromagnetic shielding.

◆Body-in-White (BIW) Structures

Hydroforming with 6016-T4 aluminum sheets for complex shapes.

◆Heat Exchangers

Thin-walled 3003 aluminum foils for radiators

Explore Mingtai’s 6000-series aluminum sheets

Aluminum vs. Steel vs. Carbon Fiber: Key Properties Comparison

| Property | Aluminum | Steel | Carbon Fiber |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.8 | 1.5-2.0 |

| Strength-to-Weight | High | Moderate | Very High |

| Tensile Strength (MPa) | 70-700 (alloy-dependent) | 400-2000 (grade-dependent) | 500-7000 (fiber/resin-dependent) |

| Corrosion Resistance | Excellent (oxidizes superficially) | Poor (requires coating) | Excellent (inert) |

| Thermal Conductivity | High | Moderate | Low |

| Cost (Relative) | $$ | $ | $$$$ |

| Recyclability | 95%+ recyclable | 100% recyclable | Limited (complex process) |

| Machinability | Easy (soft, ductile) | Moderate (harder) | Difficult (requires specialized tools) |

| Typical Applications | Aircraft panels, EV battery trays, heat exchangers | Bridges, automotive frames, machinery | Aerospace components, luxury car bodies, sports equipment |

4. Industry Trends

◆The Rise of Multi-Material Design

By 2030, aluminum will account for 18% of vehicle curb weight.” – DuckerFrontier Report.

◆Regulatory Pressures

Euro 7 emissions standards driving OEM adoption.

◆AI-Driven Material Optimization

Generative design software reducing material waste by 30%.

5. Mingtai’s Solutions

◆Custom Alloy Development

Tailored 8000-series alloys for high-strength brackets.

◆Precision Processing

CNC cutting, T4/T6 tempering, and anti-fingerprint coating.

◆Global Compliance

IATF 16949, ISO 14001, and REACH compliance.

Need a lightweighting partner? [Contact Our Engineers]