Introduction

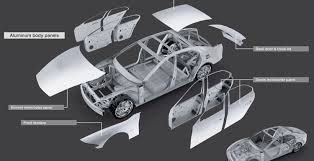

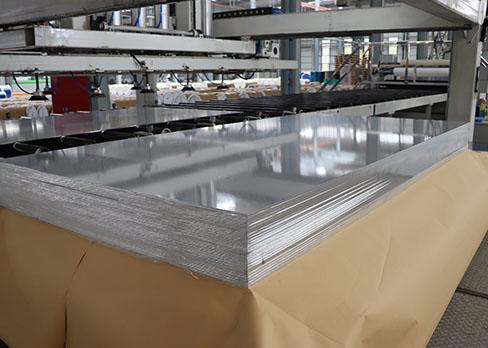

Aluminum sheet plate is an aluminum alloy material with light weight, high strength, corrosion resistance and good plasticity. The flat and thin aluminum sheet features enable aluminum sheet to be widely used in the automotive industry. Automotive aluminum sheet has excellent formability and flexibility. Aluminum sheet for automotive can be easily molded into complex shapes using various techniques such as stamping or bending without affecting its structural integrity, which also makes aluminum sheet well suited for various parts on the automotive car.

Products

1060 Aluminum Sheet Coil for Automobile

Learn More1060 aluminum alloy, like 1050 aluminum alloy, belongs to the 1000 series pure aluminum alloy. Although its strength is not high, it has excellent weldability, formability, good corrosion resistance, as well as excellent thermal conductivity and electrical conductivity. It is usually used in automobile manufacturing in the form of coils, strips and foils. The common states of 1060 aluminum for automobiles are O, H14 and H24.

5754 Aluminum Sheet Plate for Automobile

Learn More5754 automotive aluminum sheet is one of the widely used 5754 aluminum alloys. It is an ideal material in automobile manufacturing due to its light weight, high strength, excellent corrosion resistance and good formability. It can not only improve the fuel economy of the vehicle, but also ensure the rigidity and durability of the vehicle body. It is an indispensable material choice in the modern automobile industry. 5754 O aluminum sheet is the most commonly used state in automobile manufacturing. Its good ductility can be easily formed. It is the first choice for automobile body shells. It can also be used to manufacture automobile doors, roofs, engine underbody guards, automobile fuel tanks, etc.

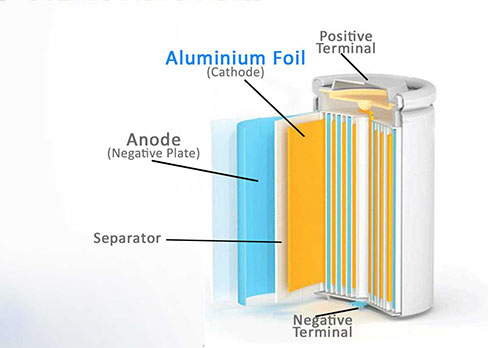

3003 Aluminum Sheet Coil for Automobile

Learn More3003 automotive aluminum sheet is a typical Al-Mn alloy with good formability, good corrosion resistance and weldability, and plays an important role in automobile lightweighting. Common states include O, H14 and H24. It is the preferred material for the power battery shell of new energy vehicles and the most widely used material for automotive water cooling plates.

5052 Aluminum Sheet for Automobile

Learn More5052 aluminum sheet is also a kind of aluminum sheet widely used in automobile manufacturing. It has moderate strength, good fatigue resistance, strong plasticity, good corrosion resistance, mature processing technology and stable performance. 5052 O/H32/H34/H26 is a commonly used alloy state in automobile manufacturing. Its application is mainly concentrated on parts that require lightweight, high strength, good corrosion resistance and easy processing, such as automobile fuel tanks and automobile parts. With the continuous improvement of the automobile industry's requirements for lightweight and environmental protection, the application scope of 5052 aluminum sheet in automobile manufacturing is expected to expand further.

5083 Aluminum Sheet Plate for Automobile

Learn More5083 automotive aluminum shee plate is one of the typical applications of 5083 aluminum alloy. Its material properties are high strength (higher than 5182 aluminum plate), light weight, excellent corrosion resistance, outstanding weldability and good formability. The common states of 5083 automotive aluminum sheet include O state (complete annealing state), H111 (mild work hardening state) and H32 (1/4 hardening state). Its mechanical properties improve evenly with decreasing temperature, and its fracture toughness also improves accordingly. It is a good automotive cover alloy, especially suitable for internal and external welded sheet metal structures such as commercial vehicles, various special vehicles, and semi-trailers.

5182 Aluminum Sheet for Automobile

Learn More5182 aluminum alloy belongs to AL-Mg alloy, which has a wide range of applications. It is a commonly used aluminum for automobiles, mainly used in the manufacture of automobile bodies. The production process of automobile doors, hoods and trunk lids mainly includes blanking, stretching, trimming, flanging and side flanging. Among them, stretching forming is the key process to ensure the quality of part forming. 5182 automotive aluminum sheet has good stamping performance, is easy to process and form, and is easy to weld. It is the preferred material for aluminum sheet for four doors and two covers.

6061 Aluminum Sheet Plate for Automobile

Learn More6061 aluminum alloy is an aluminum alloy widely used in automobile manufacturing. It is favored for its excellent mechanical properties, weldability and corrosion resistance. 6061 automotive aluminum sheet is mostly used in automobile manufacturing in the form of aluminum sheet or profile. Common tempers include O, T4, T451, T6, T651, etc. Among them, 6061 O aluminum sheet is in annealing state, the softest, suitable for various bending processes; 6061-T4 aluminum sheet is naturally aged and has medium strength; 6061-T6 aluminum sheet is artificially aged, has the highest strength and hardness, and is widely used in structural applications. 6061 aluminum sheet can be used to manufacture vehicle frames, automobile seat frames, anti-collision beams and automobile wheels.

The performance of aluminum plate for auto

1.Good formability is required pinholes and corrosion marks;

formability of sheet metal refers to its ability to withstand shape changes in the stamping process.Formability can be evaluated by a formability test. At present, there are a large number of test results on the formability of steel plates, but the formability test results of aluminum alloy plates can fully meet the needs of automobile performance.

2. Certain aging stability

The property that aluminum alloy sheets do not age when stored at room temperature is called aging stability. Because aging will make the alloy elongation at the yield point during tensile deformation, that is, Lude ribbon, resulting in uneven surface deformation and wrinkling during stamping, affecting the appearance of stamping parts; Plates often need to be transported and stored for some time from production to parts stamping. Generally, plates are required to be stored at room temperature for 6 months without aging.

3. Good bake hardenability

After stamping, automotive stamping parts will also produce aging when they are baked with paint, which will increase their yield strength, which is called bake hardening. High bake hardenability will give parts high dent resistance. Mingtai Aluminum hopes that the baking hardenability of aluminum alloy plate is the best and compatible with the painting process of steel plates because most car enterprises currently design the paint baking process for steel plates, and the baking hardenability of aluminum alloy plates is obviously different from that of steel; The bake hardenability of the material can be evaluated according to relevant standards.

4. Good flanging ductility

When stamping flanging of automobile outer panel, the cracking resistance of plate is called flanging ductility. Therefore, an aluminum alloy plate is required to have good flanging ductility to ensure no cracking during flanging. The flanging ductility of the plate is related to the total elongation of the plate and the internal structure of the material. The flanging ductility can be tested by cold bending test, but the sensitivity of strain rate is not considered in general cold bending, while the deformation is fast and the strain rate is large during stamping flanging, so there are higher requirements for flanging ductility.

5. Good surface freshness

An aluminum alloy plate is different from a steel plate, and its grain size is much larger than that of steel. Under the coarser grain, if the grain size is uneven, it will lead to uneven deformation like rope grommet on the surface of stamping parts along the rolling direction. This surface defect is also called Luo Ping line, resulting in inconsistent surface gloss after painting. Therefore, aluminum alloy plate for automobile needs to have better surface gloss.

6. Surface treatment and coating performance

Before painting, the surface of iron and steel materials should be pickled and Phosphated to improve the adhesion between the surface of stamping parts and paint and improve their corrosion resistance; Because there will be a closely bonded oxide film on the surface of aluminum alloy, the surface treatment method before painting is different from that of iron and steel materials. Instead of using the general acid phosphating method, chromium treatment is adopted. Considering the toxicity of hexavalent chromium to the human body, chromium-free or low chromium treatment technology has been developed in recent years, which can meet the needs of enterprises.

Detailed description of aluminum alloys for cars

| Alloy | Description | Typical Car Applications |

|---|---|---|

| 5052 aluminum sheet | Non-heat-treatable aluminum-magnesium alloy with high strength, corrosion resistance, and good weldability. | Body panels, fuel tanks, interior components |

| 5754 aluminum sheet | Non-heat-treatable aluminum-magnesium alloy with excellent corrosion resistance, particularly in marine and industrial environments. | Floor panels, fuel tanks, truck side panels |

| 6061 aluminum sheet | Heat-treatable aluminum-magnesium-silicon alloy with excellent strength, corrosion resistance, and good machinability. | Chassis, frames, suspension components |

| 6063 aluminum sheet | Heat-treatable alloy known for superior surface finish, moderate strength, and good corrosion resistance. | Roof rails, trim, decorative parts |

| 6082 aluminum sheet | High-strength heat-treatable alloy with good corrosion resistance and excellent mechanical properties. | Crash management systems, structural components, chassis parts |

Typical Dimensions of Aluminum Sheets

| Alloy | Thickness (mm) | Width (mm) | Surface Finish |

|---|---|---|---|

| Aluminum 5052 | 0.5 – 12 | 1000 – 2000 | Mill, polished |

| Aluminum 5754 | 0.6 – 8 | 1000 – 1500 | Mill, anodized |

| Aluminum 6061 | 0.5 – 25 | 1000 – 2500 | Mill, brushed |

| Aluminum 6063 | 0.8 – 12 | 1000 – 1500 | Anodized, polished |

| Aluminum 6082 | 1.0 – 30 | 1200 – 2000 | Mill, painted |

If you haven’t found the information your want Please kindly send to

sales@mingtai-al.com