Introduction

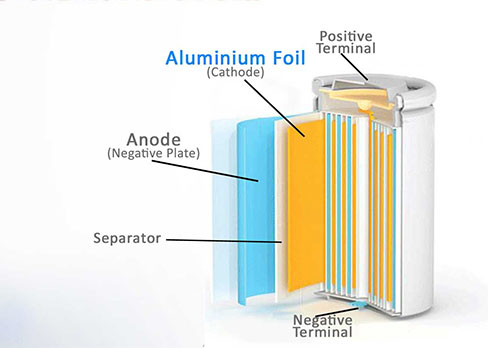

Battery aluminum foil is one of the base materials for new energy vehicle lithium batteries. Generally, the lithium-ion battery industry uses rolled aluminum foil as the positive electrode collector. The main constituent materials of lithium-ion batteries include electrolyte, separator materials, positive and negative electrode materials, etc. The positive electrode includes a current collector composed of aluminum foil and lithium cobaltate or lithium iron phosphate. At present, general battery foil products generally require a strength of ≧180Mpa, and it is pure aluminum alloy, which means that battery foil is a product that has extremely strict requirements on the base material of aluminum foil, and battery foil requires the thinnest thickness and highest strength, the highest surface dyne value, the smallest thickness difference, the best plate shape, and the cleanest surface.

1235 aluminum foil, 1060 aluminum foil are widely used on aluminum foil for lithium-ion batteries. The product has uniform surface color, clean, flat plate shape, no obvious oil stains; strength > 180Mpa, elongation > 1.5%, wettability > 32 dyne, can effectively Improve the adhesion between the active material and the current collector, and reduce the manufacturing cost.

Products

The Product Features of Pharmaceutical Aluminum Foil

◆ the surface of the aluminum foil is uniform, clean and flat, without obvious roller marks, pits, pinholes and corrosion marks;

◆ there are no rolling defects such as creases, mottling and bright lines on the surface of the aluminum foil;

◆ there is no color difference on the surface of aluminum foil;

◆ surface is free of oil, no serious oil smell, and no oil spots visible to the naked eye;

◆ surface tension, the dyne pen test is not less than 32 dyne;

Specification of Battery Shell Foil

| Alloy | State | Thickness tolerance(MM) |

Width tolerance(MM) |

Pipe core specification(MM) |

Tensile strength/Mpa | Elongation/% |

Dyne value(N/M²) |

| 1235 | H18 | 0. 012-0. 016 | ±3% | Φ76. 2 Φ152. 4 |

170-200 | ≥1. 2 | ≥31*10-3 |

| 0. 0161~0. 020 | ≥1. 4 | ||||||

| 0. 021-0. 035 | ≥1. 6 | ||||||

| 1060 | H18 | 0. 012~0. 016 | 165~190 | ≥1. 2 | |||

| 0. 0161-0. 020 | ≥1. 4 | ||||||

| 0. 021-0. 035 | ≥1. 6 | ||||||

| 1070 | H18 | 0. 012-0. 016 | ≥180 | ≥1. 2 | |||

| 0. 0161-0. 020 | ≥180 | ≥1. 4 | |||||

| 0. 021~0. 035 | ≥170 | ≥1. 6 |

If you haven’t found the information your want Please kindly send to

sales@mingtai-al.com