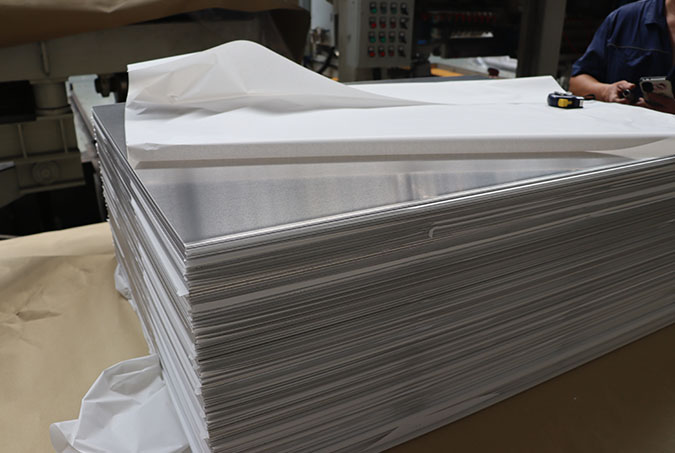

Characters of 5052 – HO Aluminum Sheet

Among aluminum alloy materials, the 5052 – HO aluminum sheet is highly favored for its unique properties. The 5052 alloy belongs to the non – heat – treatable 5000 series of aluminum alloys, and the “HO” temper imparts special properties to it.

Chemical Composition Lays the Foundation

The 5052 – HO aluminum sheet has magnesium (Mg) as its main alloying element, with a content ranging from 2.2% to 2.8%. Magnesium strengthens the alloy, and the formed solid solution improves the strength and hardness of the material. A small amount of chromium (Cr), approximately 0.15% – 0.35%, can enhance the stability of the surface oxide film and improve corrosion resistance. In addition, trace elements such as silicon (Si) and iron (Fe), although present in small quantities, also affect the casting and mechanical properties of the aluminum sheet.

Excellent Mechanical Properties

The 5052 – HO aluminum sheet has moderate strength, making it suitable for scenarios where a certain level of structural strength is required but not overly strict, such as the construction of lightweight structures. Its outstanding ductility and formability are also remarkable. It can be easily shaped into various forms through processes such as rolling, bending, and stamping, facilitating the manufacture of products with complex designs and finding wide applications in the automotive parts and packaging industries.

Good Corrosion Resistance

A thin oxide film naturally forms on the surface of the aluminum sheet. This film serves as a natural protective barrier in general environments, effectively blocking further oxidation and corrosion. Even in environments with moderate humidity or chemical exposure, it can remain in good condition for a long time. In coastal or industrial environments, the addition of chromium enhances its corrosion resistance, offering a high cost – performance ratio.

Outstanding Weldability

The 5052 – HO aluminum sheet can be welded using common methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, with good welding results. This facilitates the connection of different parts during the manufacturing process and expands its application scope.