Introduction

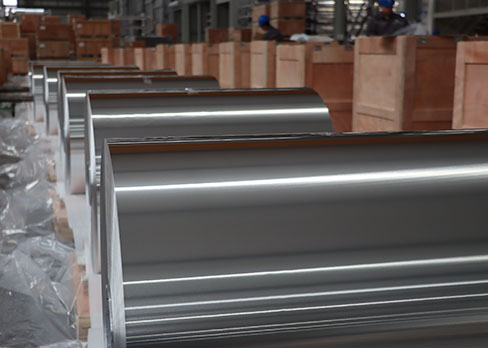

Mingtai Aluminum is a manufacturer of aluminum foil raw materials for lunch boxes (only providing polished aluminum foil base material without later processing processes such as lamination and charring). It focuses on 3004 food-grade aluminum foil for lunch boxes. It has the advantages of clean surface, safe and sanitary products, and high elongation. It is a supplier of aluminum foil raw materials for various aluminum lunch box manufacturers at home and abroad.

Aluminum foil lunch box is a widely used tableware. The thickness of aluminum foil lunch box is generally 0.03mm~0.20mm, which can be divided into wrinkled and wrinkle-free. It can also be divided into disposable and reusable. It is often called tinfoil lunch box in China. In fact, it is 3 series or 8 series aluminum ingot raw material, which is cold-rolled or hot-rolled into aluminum foil master roll with uniform thickness, smooth surface, no pinholes, no dust particles, and no odor. It is formed by one-time automatic cold stamping with special equipment and mold.

Products

8011 Aluminum foil for containers

Learn More8011 Aluminum foil for containers has a smooth surface, good sealing performance, light weight, durability, good barrier properties, which can effectively prevent moisture, oxygen and other gases from entering the packaging, maintaining the freshness and flavor of food. The most important thing is that 8011 aluminum foil is easy to process and can be formed into various shapes. It is perfect for making food containers, safe and healthy. Non-wrinkle aviation lunch box materials can use 8011 aluminum foil.

3003 Aluminum foil for containers

Learn More3003 Aluminum foil for containers has high electrical conductivity, which can minimize the time and energy associated with food processing, refrigeration and reheating, is suitable for high temperature sterilization and heat sealing. 3003 Aluminum foil can be heated in a variety of ways. 3003 Aluminum foil is easy to form and seal, can be painted to ensure food hygiene. 3003-H24 Aluminum foil is a commonly used material for containers. 3003-H24 Aluminum foil is mainly used for food containers, punched food containers, pans, lunch boxes, food packaging, etc.

3004 Aluminum foil for food packaging

Learn More3004 Aluminum foil for food packaging and containers. 3004 Aluminum foil container has a beautiful appearance and good thermal conductivity. It can be heated directly on the original packaging with ovens, microwaves, steamers and other kitchen appliances. 3004 Aluminum foil for container has high hardness, good load-bearing, and better stamping effect than 3003 aluminum foil. 3004 Aluminum foil has the price advantage of 8011 aluminum foil and the strength advantage of 3003 aluminum foil.

8006 Aluminum Foil for Containers

Learn More8006 aluminum foil as a representative is the exclusive aluminum foil for aerospace lunch box materials. It has a tensile strength of 125-135Mpa. The edges of the stamped lunch box have no wrinkles, and the appearance is high-grade and beautiful. For another lunch box material 8011 aluminum foil, which has a tensile strength of 120-170Mpa and an elongation greater than 8%, the difference in mechanical parameters between this two lunch box materials is small. However, 8006 aluminum foil for lunch box material has higher elongation and cup convexity than 8011, 3003 aluminum foil.

The Product Features of Container Aluminum Foil

◆ Safety .8011 aluminum foil is a food contact grade packaging material. It is non-toxic and harmless and has a good guarantee for food safety. Aluminum foil containers are packaging materials that can withstand high and low temperatures and is a stable molecular structure. Compared with plastic lunch boxes, container aluminum foil can go from the refrigerator to the oven to the dining table without changing the containers. After multiple uses in the oven, the exterior remains shiny and food retains its color and flavor.

◆ Barrier properties.Barrier to air, light and moisture, protect the original flavor of food, and extend the shelf life of food. It is convenient for catering companies, restaurants, supermarkets and households to store, avoiding product deterioration, extending shelf life and reducing food waste.

◆ Good thermal conductivity. 8011 aluminum foil has good thermal conductivity and can speed up baking and freezing, because it can dissipate heat evenly and make food evenly heated.

◆ Flexible.Can be molded into different shapes and sizes, and food containers can be mass-produced.

◆ Recyclable. Aluminum foil container is lightweight, tight sealing, safe, easy to use and transport, the price is the same as plastic materials. Used lunch boxes can be recycled and reused, which reduces pollution and saves resources.

Specification of Container Aluminum Foil

| Alloy | 3003, 3004, 8011, 8079, 8006, 5005, 5052, 1100 |

| Temper | O/HO,H14,H16,H22,H24,H26 |

| Thickness (mm) | 0.03-0.20 (±8%) |

| Width (mm) | 100-1600 (±1%) |

| Coil ID | 75mm, 152mm |

| Coil OD | 400-1200 |

| Quality | For high precision aluminum foil: staggered layer ≤0.5, tower shape ≤1.0, pinhole diameter ≤0.1 |

| Certificate | SGS, FDA, ISO |

| Packing | Export standard |

| Application | Baking/cake/soup/food packing |

| Sample | Free A4 sample |

If you haven’t found the information your want Please kindly send to

sales@mingtai-al.com