Introduction

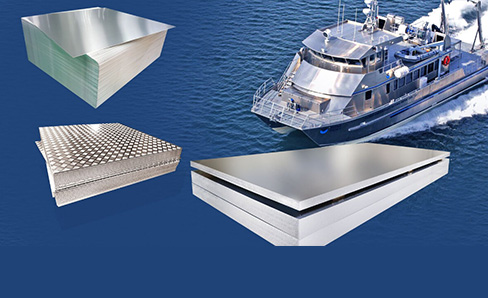

Marine-grade aluminum plates predominantly comprise 5xxx and 6xxx series alloys, notably including 5083, 5086, 5454, 5754, 5052, and 6061 aluminum sheets. Commonly used tempers encompass H111, H112, H321, and H116, among others. These marine-grade aluminum sheets are primarily employed for ship decks, engine mounts, hull sides, bottom outer plates, and various other components. Our marine aluminum plates have obtained classifications from CCS, LR, NK, BV, and ABS. The products meet shipbuilding standards in terms of mechanical properties, welding characteristics, and corrosion resistance.

Products

5083 Marine aluminum sheet plate

Learn More5083 Marine aluminum sheet plate: 5083 aluminum plate is the strongest non-heat treatable aluminum alloy that maintains its strength even after welding, has high strength and low ductility fracture properties and is highly corrosion resistant and good anti-rust function, can resist the corrosion of the hull by sea water, marine climate and harsh environments, reduce maintenance costs such as oiling, is great significance to the safety and life of ships. 5083 marine aluminum sheet plate is mainly used for decks, engine bases, ship sides, bottom outer plates, keels, and hull structural materials. The common tempers of 5083 aluminum sheet plate for shipbuilding are O, H111, H112, H116 and H321. 5083-H116 and 5083-H321 aluminum sheets plates have better corrosion resistance and are more suitable for the marine underwater environment than H111 and H112 tempers.

5086 Marine aluminum sheet plate

Learn More5086 Marine aluminum sheet plate: 5086 aluminum plate is a typical anti-rust aluminum, which is widely used in occasions that require high corrosion resistance, good weldability, and medium strength, such as weldable parts for ships and automobiles. 5086 aluminum sheet has high electrical conductivity and excellent corrosion resistance. 5086 aluminum sheet can be strengthened by strain hardening and cold working until it is stronger than 5083. While 5086 aluminum sheet is compatible with several welding methods, arc welding is the alloy of choice. 5083 and 5086 aluminum plates are commonly used in ship hull structures and decks, ship sides, bottom outer plates, etc. 5086 aluminum plate for the ship can achieve energy saving, emission reduction and improve ship performance.

5052 Marine aluminum sheet plate

Learn More5052 Marine aluminum sheet plate: 5052 aluminum plate is a common marine grade aluminum plate. It has excellent weldability, good corrosion resistance, cold workability, medium strength, good formability and fatigue resistance; is suitable for manufacturing economical aluminum ships. 5052 Marine grade aluminum plate is the material of choice for high-speed ships such as fast ferries, yachts and offshore work boats. It is widely used in the manufacture of ship sheet metal parts, bottom plates, portholes, bottoms, and side plate of shipbuilding containers. 5052-H32 aluminum sheet plate and 5052-O aluminum sheet plate for small freshwater lake yachts hulls, because fresh water is not as corrosive as seawater.

5454 Marine aluminum sheet plate

Learn More5454 Marine aluminum sheet plate: 5454 aluminum plate has very good corrosion resistance, rust resistance and weldability, especially to seawater and general environmental conditions. 5454 Aluminum plate is a non-heat-treatable alloy that can be strengthened by cold working. Its strength is 20% higher than medium-strength 5052 aluminum plate. 5454 Marine grade aluminum and 5083 marine grade aluminum are sister alloy, has lower stress corrosion levels when operating in the 150°F to 300°F range. It has excellent anti-rust properties, high fatigue strength and excellent weldability. 5454 Aluminum sheet plate is usually used in environments with high rust prevention requirements, such as marine facility pipelines, aluminum tank car bodies, automobile wheels, ships and other welded structures. The commonly used alloy is 5454-H32 aluminum plate.

5754 Marine aluminum sheet plate

Learn More5754 Marine aluminum sheet plate: 5754 aluminum sheet is a low magnesium marine aluminum alloy used in the shipbuilding industry, has superior corrosion resistance, good weldability and moderate strength, and is ideal for marine industry and other industrial applications with corrosive operating environments. 5754 Aluminum alloy is stronger than 5251. This high strength makes 5754 aluminum sheet plate ideally suited for marine applications requiring a combination of strength and resistance to seawater corrosion. 5754 Marine grade aluminum plate is commonly used in shipbuilding, marine applications, finishing industry equipment. The common tempers of 5754 aluminum sheet plate are H22, H32, H111.

Specification of Marine Grade Aluminum Sheet Plate

|

Alloy |

Temper |

Thickness (mm) |

Width (mm) |

Length (mm) |

|

5083 |

O,H111,H112,H116, H24,H32,H321 |

1.50-120 |

≤3100 |

1000-16000 |

|

5086 |

O,H111,H112,H116,H321 |

1.50-120 |

≤3100 |

1000-16000 |

|

5052 |

O,H111,H112,H24,H32,H34,H36 |

1.50-120 |

≤3100 |

1000-16000 |

|

5754 |

O,H111,H112,H24,H32,H34,H36,H38 |

1.50-120 |

≤3100 |

1000-16000 |

|

5454 |

O,H111,H112,H24,H32,H34,H36,H38 |

1.50-120 |

≤3100 |

1000-16000 |

|

5456 |

O/H111/H112/H116/H321 |

1.50-120 |

≤3100 |

1000-16000 |

|

5154 |

O,H111,H112,H24,H32,H34,H36 |

1.50-120 |

≤3100 |

1000-16000 |

|

6061 |

O,T4,T6,T651 |

≤60 |

≤3100 |

1000-16000 |

|

6063 |

T5/T6 |

≤60 |

≤3100 |

1000-16000 |

|

Standard |

GB/T 3880, EN14286, EN485, ASTM B209, or according to customer’s special requirements |

|||

|

Certification |

DNV, GL, ABS, CCS, BV, LR |

|||

Mingtai: supplier for high quality marine grade aluminum plate

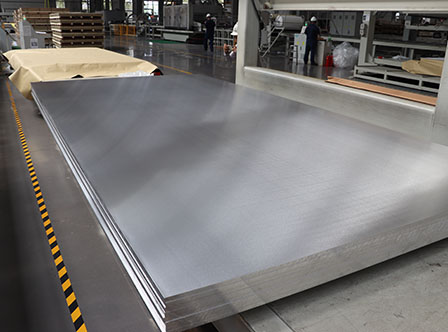

Mingtai is one of the world's largest manufacturers and exporters of marine grade aluminum plates, certified by multiple classification societies. Obtain the "World License" for marine aluminum plates. The product is widely used in ship deck, side, bottom, hull, deck, keel, chimney and other components. It can be used to manufacture various ships ranging from small yachts to tens of tons of cruise ships.

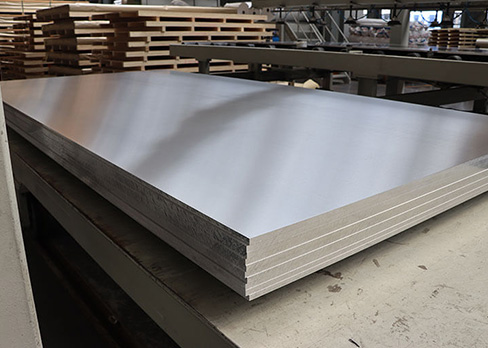

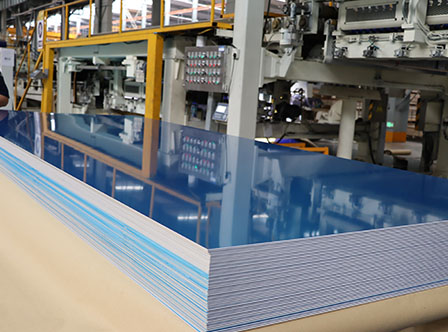

The introduction of the world's most advanced equipment, the 3000T stretching machine, can perform permanent tensile plastic deformation of 1.0% -3.0% on the plate within the specified time according to process requirements. By transitioning from elastic deformation to plastic deformation, residual internal stress after quenching is eliminated, ensuring that the product does not deform during processing.

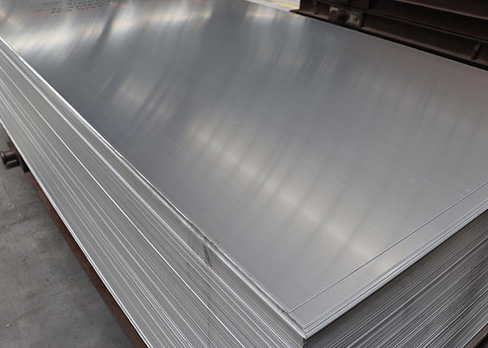

● Mingtai marine aluminum plate has no oil spots, ripples, or scratches.

● Mingtai marine aluminum plate has no burrs, no surface rolling marks, and neat cutting edges.

● Mingtai adopts advanced production processes to reduce the tendency of ingot cracking and improve the surface quality of rolled plates.

If you haven’t found the information your want Please kindly send to

sales@mingtai-al.com