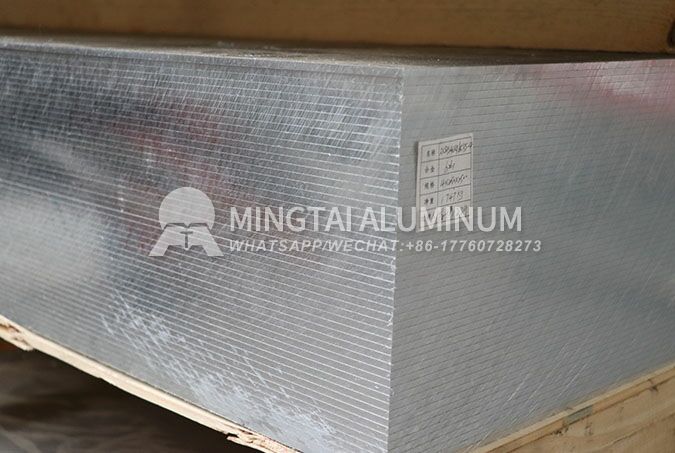

Vietnam 5052H32 aluminum sheet

In Vietnam’s booming marine engineering and transportation equipment market, 5052-H32 aluminum alloy sheet has become the material of choice for shipbuilding and pressure vessel manufacturing, thanks to its exceptional corrosion resistance and weldability. Mingtai Aluminum, Asia’s leading aluminum processor, specializes in supplying high-standard 5052-H32 aluminum sheets to Vietnam and Southeast Asian markets, meeting rigorous marine environment requirements.

Technological Edge: Quad-Layer Corrosion Protection

Mingtai’s 5052-H32 aluminum sheet achieves four-layer performance breakthroughs through proprietary alloy formulation:

●Corrosion Barrier: Al-Mg alloy substrate with chromate conversion coating passing 3000h neutral salt spray test

●Welding Optimization: Dedicated welding parameter packages ensuring 85% parent material strength for TIG/MIG joints

●Formability: Over 22% elongation enabling 80mm deep stamping without cracking

●Mechanical Performance: 195MPa yield strength and 230MPa tensile strength for structural applications

The product passes SGS material composition verification, complying with ASTM B209 and EN 485-2 international standards, suitable for ship hulls and chemical tankers.

Production System: Smart Manufacturing for Quality Assurance

Mingtai operates a 1,450,000-ton/year specialized aluminum sheet plant in Henan, China, equipped with Germany’s SMS hot tandem mills and UK’s Achenbach stretch leveling lines, enabling full-process intelligent production from melting to finishing. While maintaining no overseas warehouses, strategic partnerships with DHL, FedEx ensure 3-5 business day delivery to Vietnam’s major port cities like Hanoi and Haiphong, complemented by free sample testing services.

Success Story: 60-Ton Shipbuilder Order Fulfillment

Recently completed a 60-ton 5052-H32 aluminum sheet order for a leading Vietnamese shipbuilder:

●1.2mm×1170mm×1830mm ×30 tons

●1.2mm×1170mm×1920mm ×30 tons

Application in 300-ton fishing vessel hull components demonstrated:

●0.003mm/year corrosion rate in salt spray environment

●<0.2% dimensional change from -20℃ to 60℃

●±1mm welding deformation control

●Stock Portfolio: Standardized & Customized Solutions

Standard inventory includes:

●Thickness: 0.8-6.0mm (0.1mm precision adjustable)

●Width: 900-2200mm (including non-standard 1170mm)

●Length: Coil/2000-6000mm (cut-to-size)

Customization services:

●Surface roughness control Ra0.4-1.6μm

●Double-sided protective film application

●Laser cutting subcontracting

Applications: Expanding Marine Industrial Frontiers

Typical applications include:

●Yacht decking leveraging 5052-H32’s fatigue resistance

●LNG tankers with double-sided TIG welding

●Offshore wind platforms maintaining structural integrity in humid environments