Wine cap foil 1235_8011 aluminum foil

The use of aluminum foil in wine packaging (especially bottle caps or top labels) can effectively isolate oxygen, light and moisture, prevent wine from oxidation and deterioration, and extend the shelf life. Aluminum foil is thin and light, easy to calender and form, and can be adapted to bottle cap designs of different shapes, while reducing transportation costs. It has good decorativeness and brand value. The surface of aluminum foil can be used through printing, hot stamping and other processes to enhance the appearance of the product and enhance the visual appeal of high-end wine brands.

Wine cap_What are the specifications of aluminum products for bottle cap materials

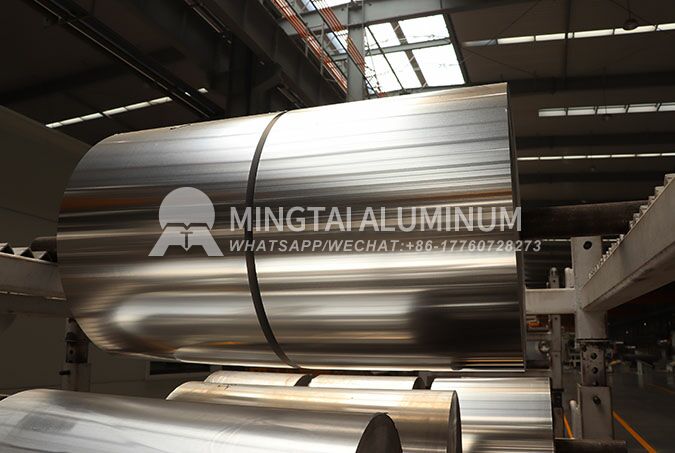

Aluminum alloy grades for wine cap_bottle cap materials: 1235/3004/8011/8079. There are different standardized processes for bottle cap materials with different uses. Mingtai Aluminum’s main equipment includes 1+4 hot rolling, casting and rolling mill, annealing furnace, cold rolling mill, straightening machine, slitting machine, and shearing machine. The range of bottle cap materials that can be produced is 0.145-0.30 * 464~1100 (other specifications are agreed upon according to customer needs).

Wine cap_Bottle cap material aluminum performance advantages

●Moisture-proof and sealing: The aluminum foil roll has a dense structure that can completely block water vapor, ensuring the stability of wine in a humid environment68.

●Temperature resistance: It can withstand a temperature range of -50℃ to 300℃, suitable for high-temperature sterilization or low-temperature storage processes27.

●Safety and hygiene: High-temperature annealing and disinfection are used during the production process, which is non-toxic and odorless and meets food-grade packaging standards78.

●Cost-effectiveness: Compared with other metal materials, aluminum has the advantages of both lightweight and low cost, and the processing energy consumption is low

Wine cap_Bottle cap material aluminum has become the preferred material for wine packaging due to its irreplaceable physical properties and environmental protection attributes. In the future, with the upgrading of consumption and the iteration of technology, wine cap aluminum foil will develop in a lighter and more functional direction, and market competition will drive companies to accelerate innovation and global layout.

Henan Mingtai Aluminum’s raw materials are sampled and inspected before entering the factory, and can only be used after passing the inspection. The quality of the products is controlled from the source and the production process is strictly controlled. The surface of the products produced should be flat, clean and free of oil spots. Wrinkles and serious indentations are not allowed. If you need to know more product-related information and product processing fees, or call the consultation hotline, professional professionals will give you detailed answers!